Summary

Dynamic, astute and performance driven mechanical engineer with blend of strong academic credentials and 6 years of experience in industry; completed several industry projects for local/multinational companies in mechanical field.

Projects

Experience

Product Manager

Manage and oversee the product portfolio, monitoring product performance and developing strategies for future enhancements.Harmonize and rationalize the product range based on market requirements, proposing and implementing design changes as necessary.Conduct feasibility studies and evaluations for new product development.Formulate project plans for new product development projects, secure requisite approvals, ensure resource allocation, manage project oversight throughout execution and provide regular status reports on all key initiatives.Serve the development team by making all of the new product requirements explicitly clear and work with various competence owners to help them secure their deliverables on time.Deliver prototypes on time while documenting all the issues to be solved before ramp to volume production.Drive issue resolution process to reach volume product maturity and cost targets.Coordinate cross-functional managers and respective stakeholders as and when required and maintain updated project documentation.

Manager Technical

Responsibilities:

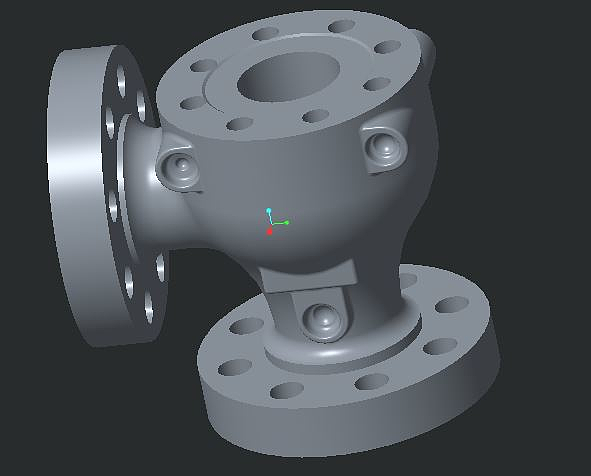

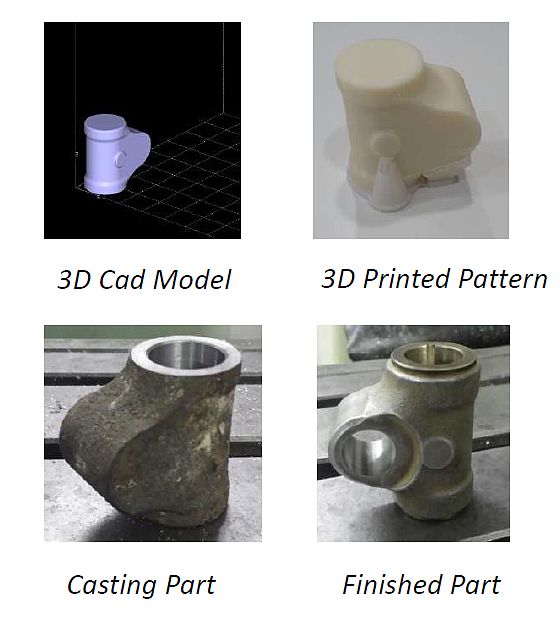

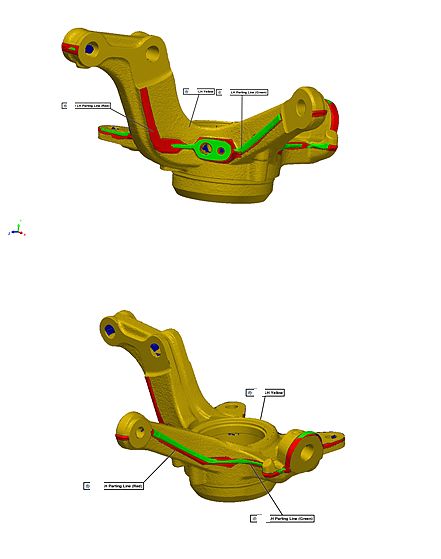

§ Leading Design section to develop mechanical equipment 3D CAD Models as per client requirement and suggest modifications for better efficiency. Perform design tweaks to improve design quality and facilitate easier assembly.

§ Review and maintain production orders, schedules to ascertain product data and specifications of products, schedule delivery dates in order to plan facility operations.

§ Leading a team of supervisors, technicians in manufacturing of parts and provide training to improve performance.

§ Ensure mechanical parts are manufactured as per given 3D CAD Model and 2D drawing.

§ Planning and undertaking scheduled preventive, predictive, and breakdown maintenance of machines installed at Factory.

§ People management to obtain desired production results with available resources

§ Diagnosing, troubleshooting and identifying solutions to resolve equipment issues.

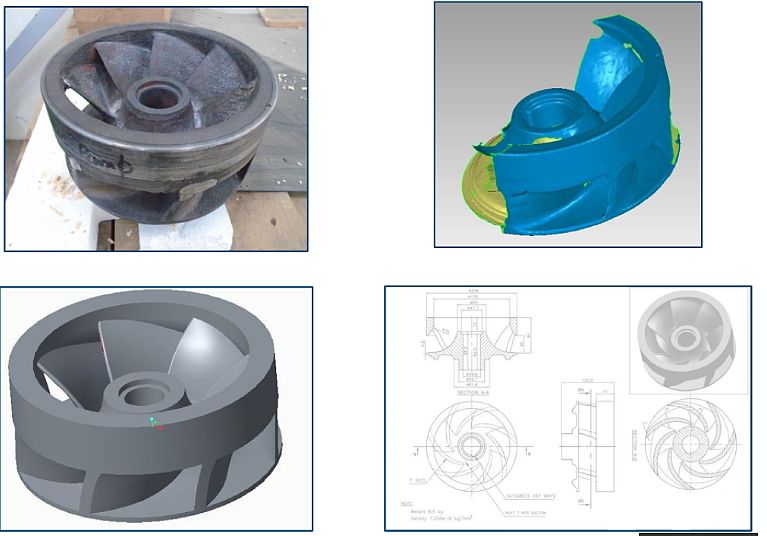

Design & Application Engineer

Develop accurate 2D CAD drawings, detailed engineering drawings, assembly drawings, manufacturing drawingsusing 3D Scanning and CAD conversion for the various industrial parts and equipment.Provide application specific assistance, including demonstrations of 3D Scanner and CAD/QC software to customers during the lead generation and early sales process.Identify client needs and provide customized solutions that best fit their requirements, supporting them in purchasing, integrating and using equipment/software.Respond to technical support inquiries and provide on-site/call assistance as required.

Service Advisor

- Ascertains automotive problems and services by listening to customer's description of symptoms; clarifying description of problems; conducting inspections.

- Prepare repair orders by describing symptoms, problems, and causes discovered, as well as repairs and services required; obtaining approval signatures; entering RO into service database system.

- Liaising with the Workshop Controller to ensure all work is carried out in the allocated time frame.