Summary

Academic Career:

BSC- (Electrical): (2008-12)

FSC (Pre Engineering): (2006-08)

Matric (Science): (2005-06)

PEC Registration No. ELECT/39961

I am working in Rupali Group of Industries (Petro Chemical) as an Electrical Engineer from March 04, 2012 yet.

Professional Career:-

By the grace of ALLAH, I passed my graduation (BS- Electrical) in 2012 and became the part of renowned organization (Rupali Group of Industries) as Trainee Engineer Electrical. After successful completion of one year training program, I was confirmed against the post of Electrical Engineer. My job responsibilities were to carryout maintenance of electrical & Instrument equipments, maintain their history records, inventory, monthly reports and also supervised them. Later on, I was transferred to PMD (Project Management Depart.), where my job responsibilities were related to Cost estimation and designing, prepared Erection/Commissioning Timelines, assisted during meetings with seller/supplier to discuss about seller/buyer scope. I have been worked as project engineer, led my team and executed projects successfully.

Projects

Experience

Dy. Manager (E&I)

Working as Dy. Manager and reporting to director operation.

AM(Electrical)

Utility (HVAC /Compressors/Chillers):

• Maintenance/Trouble shooting experienced on Carrier Refrigerant Chiller (19XL, 19DR) and IR Compressor (480KW, 7.5bar, 67m³/min.)

• Maintenance and supervised the startup activities of N2 plant.(140m³/min ,Linde )

• Installed/Commissioned of I-Water Project based on Energy Saving. (A-B VFD’s, Micro Controller logic LC-32.)

• Experienced to prepare the preventive maintenance schedules of compressors, Chillers and HVAC’s. Calibration of Control Valves, Transmitters, Sensors & switches.

Polymer Plant (100 Ton/Day).

• Responsible for troubleshooting and fault tracing in Relay logic circuits.

• Configuration and modification in DCS Yokogawa centum VP.

• Maintenance and Troubleshooting on HTM control system. (WeishauptBertram’s)

• Responsible for troubleshooting in PLC Hardware as well as in software.

• Signal Tracing between Field instruments, MCC and CCR.

• Perform and review detail engineering activities like preparation of data sheets /specification material requisition of installed instruments like control valves, control system, Field instruments.

• Calibration of all type of transmitter Pressure, Level, Flow (Rosemount, Prosonic, Dynisco etc.)

• Maintenance, Calibration and trouble shooting of field Instruments. (Transmitters, Control valves, SOV’s, Switches.)

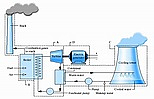

Power House (GAS / HFO / STEAM TURBINE).

Heavy Furnace Oil Engines(DAIHATSU) and Alternators (SHINKHO ELECTRIC)

4 Strokes, 8 cylinders I shape, 600 r. p.m. Diesel engine (2MW).

• Maintenance/testing of Woodward governor (UG-8), Fuel shutdown device, control relays, excitation system and its batteries checkup, bench testing generator protection relays, MCC trolleys, bearings replacement of auxiliary motors, Calibration/Testing of Engine and Alternator safeties during Top End Overhauling.

• Replacement, Testing and Commissioning of Induction type protection relays with numeric relays of generators. (Schneider, MICOM).

Education

University of Central Punjab (UCP)

Skills

Languages

Companies Followed

Endorsements

Hafiz Muhammad Adnan Yousaf

Mudasar is someone you can always trust. Great values, gets the job done, highly recommended!