خلاصہ

05 Year Experience in FMCG as Executive

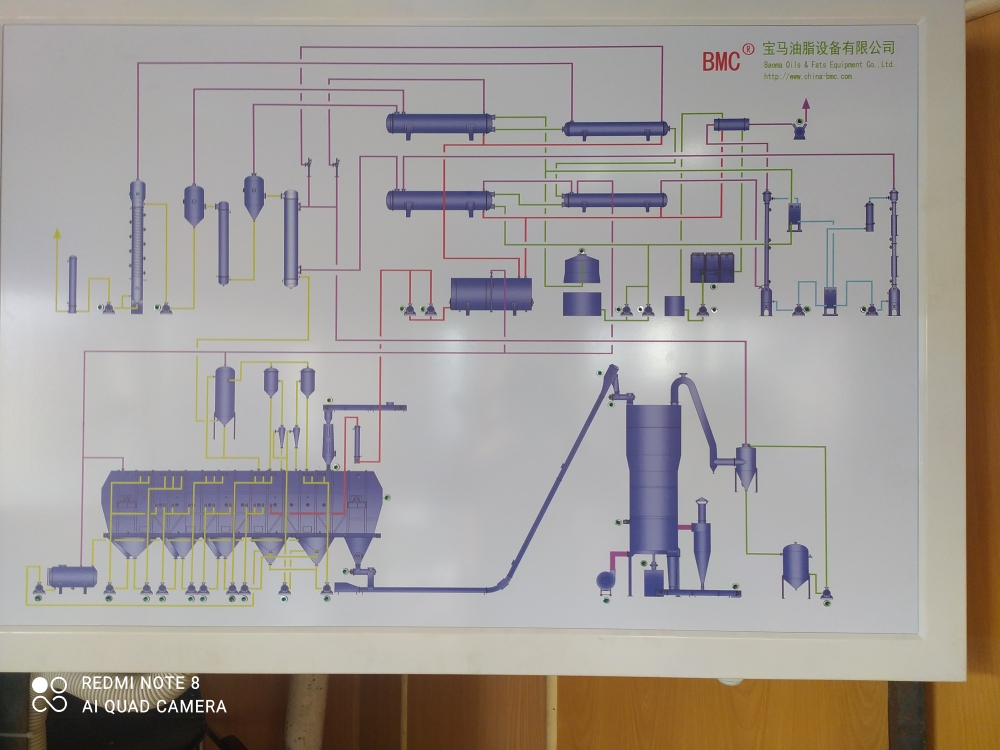

Solvent Extraction Plant

Co-ordination in Commissioning and successful running of 800 MTD Solvent Extraction

Plant( 800 MT/Day Capacity of BMC China Plant)

Supervision of Solvent Extraction Plant (400 MT/Day Capacity of D SMITH )

Safety rules implementation to ensure safe operation for human resources and plant equipments.Hands on experience of processing of different seeds on Solvent Extraction Plant

Technical evaluations of different process requirements.Monthly Report writing on material Consumption, Yield and Costing.

Manage operational aspects of crushing process to get efficient performance from entire team of production,

maintenance and quality.

Operate PLC, assist managers and manage shifts.Responsible for issuing of job work orders and record equipment history

Supervision in Operation and Maintenance of PLC controlled system, Pumps, Heat Exchanger, Pressure,Temperature and Level Control Valves.

Feasibility Report of Utilities, Chemicals and Manpower. Exchanger, Reduce utilities values and chemical consumption.Supervision in Operation and Maintenance of PLC controlled system, Pumps, Heat Exchanger,

Pressure, Temperature and Level Control Valves.

پراجیکٹس

تجربہ

Shift Engineer

05 Year Experience in FMCG as ExecutiveSolvent Extraction Plant Co-ordination in Commissioning and successful running of 800 MTD Solvent Extraction Plant( 800 MT/Day Capacity of BMC China Plant)Supervision of Solvent Extraction Plant (400 MT/Day Capacity of D SMITH )Safety rules implementation to ensure safe operation for human resources and plant equipments.Hands on experience of processing of different seeds on Solvent Extraction PlantTechnical evaluations of different process requirements.Monthly Report writing on material Consumption, Yield and Costing.Manage operational aspects of crushing process to get efficient performance from entire team of production, maintenance and quality.Operate PLC, assist managers and manage shifts.Responsible for issuing of job work orders and record equipment history Supervision in Operation and Maintenance of PLC controlled system, Pumps, Heat Exchanger, Pressure,Temperature and Level Control Valves.Feasibility Report of Utilities, Chemicals and Manpower. Exchanger, Reduce utilities values and chemical consumption.Supervision in Operation and Maintenance of PLC controlled system, Pumps, Heat Exchanger,Pressure, Temperature and Level Control Valves.

Assistant Engineer

RESPONSIBILTIESIndependent Running of Solvent Extraction Plant of 400MT per Day With Standard ParametersMaintain Daily Log SheetTroubleshooting, maintenance and Target achieving Jobs with Management and skilled Team.Daily Production and Process report writing of PHYSICAL/CHEMICALDaily Production and Process report writing of Continuous/Batch ProcessDaily Oil movement and Chemical Consumption report writing on Excel and ERP

Quality Control Engineer

RESPONSIBILTIESPreparing the chemical substances, Analyzing vegetables oil, and soap and water samples. Preparing the flavorand color for vegetables gheeSkilled with quality controltesting of oil,seed,soap,watersuch as FFA,SMP,Iodine Value,Bleaching indexSolidFatIndex,TotalFattyMatters,TDS,TH Crude Protein, KOH Solubility, Analyze quality data to recommend quality and process improvements.Complete all paper work associated with the analyses (ex., calibration logs, run logs, etc.)

Internee Engineer

Enter Description