خلاصہ

I worked at Omar Jibran Engineering Industries Ltd as a Design and Manufacturing Engineer for 4 months - (1st June,2108 to 29th September,2018). Here I supervise project of "Powered Wheel Chair" initiated by the company and I was responsible for the Parts Design and it's Assembling on NX Software by the process of Reverse Engineering (using Fero-Arm and other measuring tools). Supervision of in-house manufacturing was also my responsibility. To manufacture the parts we use milling/lathe machine, bending press, auto cutter and drilling machine.

Also, designed the electrodes on NX Software for the mold of Seal Rear Bumper for upcoming car project of Indus Motor Company. Did CAM on NX Software and used 3 axis CNC machine to manufacture it.

Moreover, worked at System Teknologies International as Mechanical Design Engineer on AutoCAD Software to Optimize the Parking Trolley, Screw Jacks and other such components in AutoCAD Software, for different purposes in Aviation Field, in collaboration with PAC, Kamra.

Furthermore, worked as Design Engineer at Mercedes Benz. Here I worked on AutoCAD Inventor software to make the heat shield using sheet metal method. Also, worked on the new AutoCAD functions for efficient and cost effective optimization of car oil sump.

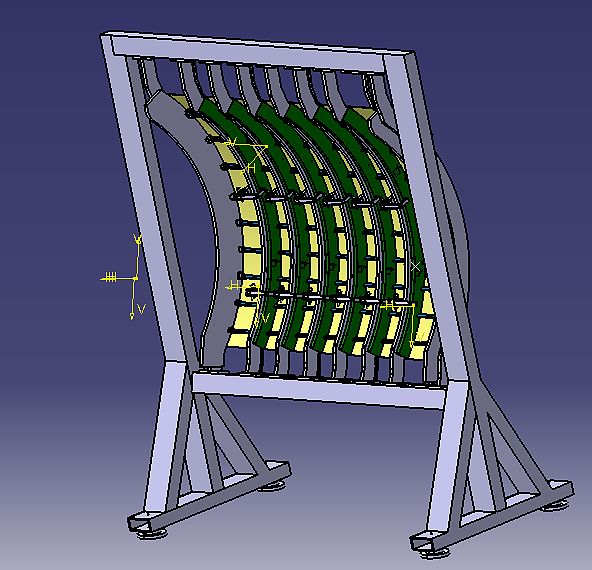

I have obtained a Bachelor Degree in Aircraft Manufacturing Engineering from Shenyang Aerospace University, China with a GPA of 7.241/10 (85.30%). My Final Year Project was based on the Designing and Simulation for machinery of aircraft panel.

پراجیکٹس

تجربہ

Design and Manufacturing Engineer

Currently, I am working in Omar Jibran Engineering Industries Ltd. as a Design and Manufacturing Engineer from June, 2018. A new project of "Powered Wheel Chair" is initiated by the company and I am responsible for the Parts Design and it's Assembling on NX Software by the process of Reverse Engineering. Supervision of in-house manufacturing also comes under my responsibility.

Moreover, I have also designed electrodes for the Mold Manufacturing of Seal Rear Bumper of an upcoming car project of Indus Motor Company.

Quality Engineer

I worked as a Quality Engineer at Omar Jibran Engineering Industries Ltd. where I managed the On-Floor inspection and Pre-Shipment Inspection by achieving lowest rejection of bad parts outflow.

Mechanical Design Engineer

Optimize the Parking Trolley, Screw Jacks and other such components in AutoCAD Software, for different purposes in Aviation Field, in collaboration with PAC, Kamra.

Design the aircraft model of “Super Mushshak” on X-Plane software, in collaboration with PAC, Kamra.

Internship in RD - Power Train Department

Presented the new AutoCAD functions to design team for efficient and cost effective optimization of car oil sump.

Drew 3D/2D design of the Heat Shield by using AutoCAD Software sheet metal method.

Actively participated in the nomination meeting of new supplier focusing on their technical ability to manufacture required parts up to company’s standards.

Proactively worked with CAx specialists in Germany.

Internship

During my internship, I have undergone generalised training sessions on airframe, propulsion and avionics systems of light and heavy aircrafts. Also observed the assembling/disassembling of the parts such as sensors attached to the ground equipment vehicles. As well as go through some electrical equipments and engine parts of the ground equipment vehicles.

Shenyang Hangda Airborne Equipment Company is an aircraft company which is approved under Chinese Civil Aviation Regulation (CAR) 147.