概要

Talented professional with an extensive background in mechanical engineering specializing in planning project coordination & mechanical maintenance. Result-oriented Associate Engineer known as a consistent team player with skilled technical abilities.

项目

工作经历

Asst. Manager Mechanical (Planning & Project Execution)

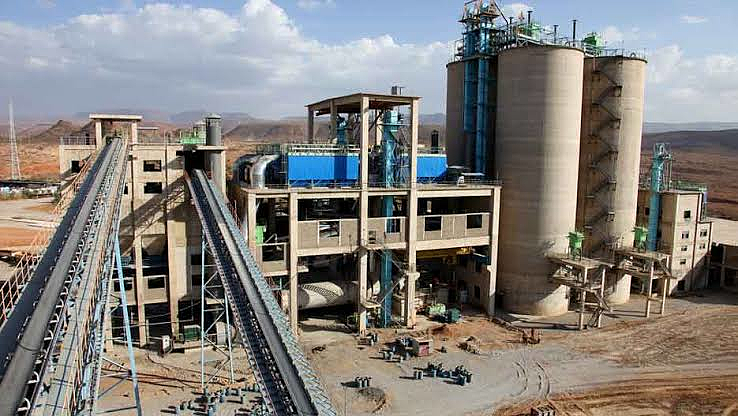

A Leading Engineering Manufacturing , Repair & Maintenance EPC contracting Company which selling customized solution to its customers & end user like Cement plant, petrochemical, oil & gas, Ready Mix Plant, Steel and many other industries in the middle east.

Assistant Manager Mechanical – Central Region Riyadh, Saudi Arabia 12/2008 – 09/2021 I joined AAT as Sr. Supervisor mechanical and after then promoted as ‘Asst. Manager Mechanical planning & project execution’ as well. My JD’s are as below.

• Followed a routine maintenance checklist. • Recorded type and cost of maintenance and repair work. • Evaluated number service team members performance each quarter. • Implemented long range planning and budget recommendations. • Performed fire alarm system installation and repair. • Followed up on all outstanding service request. • Analysed and verified all energy savings calculations to promote environmental sustainability and energy conservation. • Coordinated all aspects of production, including selection of manufacturing methods, fabrication and operation of product design. • Investigated equipment failures to diagnose faulty operation and made appropriate maintenance recommendations. • Performed on-site field surveys and wrote technical narratives in an efficient and timely manner. • Managed design and manufacturing teams to build proprietary process equipment within cost and time constrains.

Site Supervisor Mechanical

Performed data analysis and provided recommendations to achieve goals. • Played key role in designing project that resulted in positive outcome. • Saved 8% on supply costs by working closely with suppliers to ensure that all components met department quality standard. • Reduced amount of scrape product waste, saving 80,000 rupees of material per year, lowering shipping costs by 40,000 rupees annually. • Reverse engineered hardware to facilitate documentation. • Installation of electrostatic precipitators (EP’s) at Pak Cement Area.

Trainee Supervisor Mechanical

I was joined PCL as Trainee Supervisor Mechanical at limestone crusher and looked after field area reclaimer and starker i.e. After six month completion of trainee supervisor, I was promoted as supervisor mechanical on permanent basis by the management. My job responsibilities were there as below.

• Prepared maintenance plans and layouts for equipment or system arrangements and space allocation. • Prepared pipe spool/structural details and assembly drawings for shop fabrication and field errection. • Visited field area on daily basis on morning and if needed as well. • Interpreted drawings mark-ups and implemented drawings revisions provided by engineers. • Developed prototypes that saved company over 1.5 million by eliminating necessity to import foreign products.

Mechanical Technician

I was started my professional career with CDL as Mechanical Technician at mechanical workshop and after three months promoted as blow moulding operator and transferred to the bottling plant.