概要

I have more than Eleven Year hands on experience in Project Management, Production Management, Product Designing, Product Development, Designing and Manufacturing of Prototype & Production tooling for Sheet Metal (Aluminum, Mild steel, Stainless steel) and Plastic Injection and Blow Molds (PP, PVC, HDPE, LDPE, PET) for Medora Cosmetics, Kohinoor Battery Manufacturers and S. Engineering.

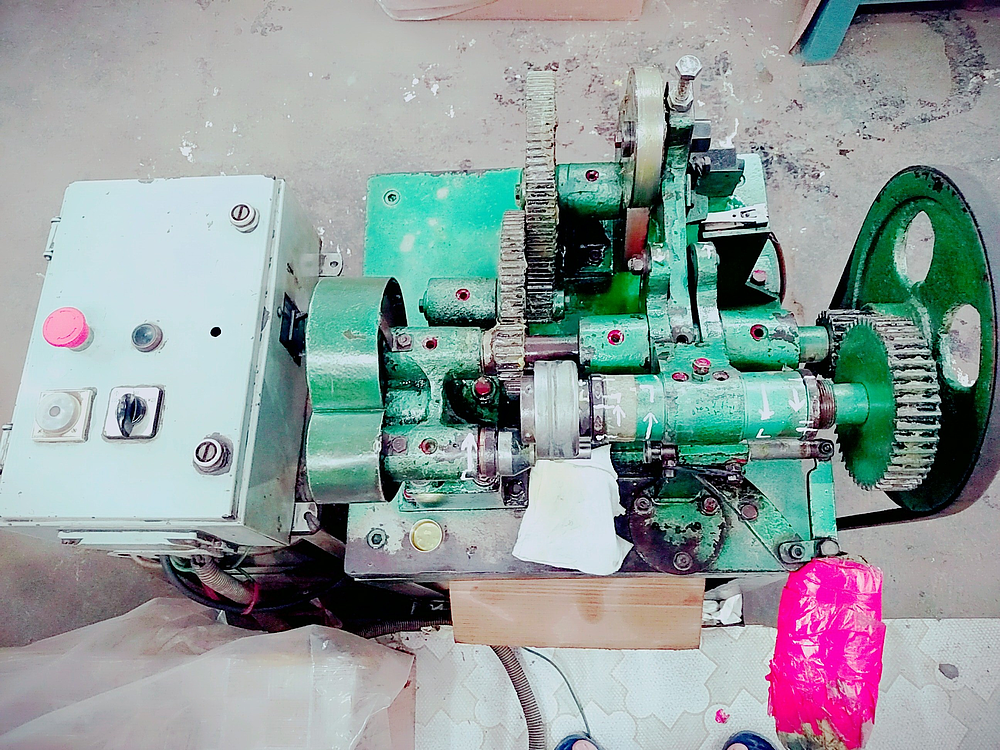

Designing, manufacturing, modification, maintenance and refurbishing of Production Machines, tooling and allied equipment.

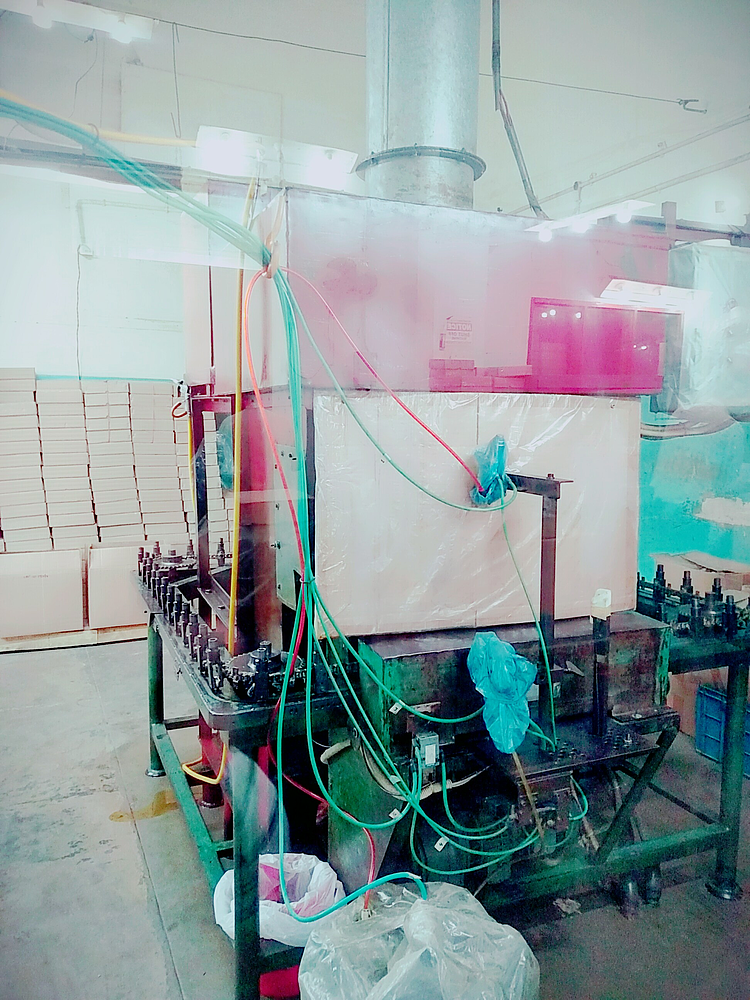

Experience with Eyelet High Speed Press, Transfer Presses, Schuler Presses, Mechanical Press Brake, CNC Hydraulic Presses, CNC Trimming & Curling / Beading & Threading machines, Engel and Hysion Injection and Blow Molding machines, Ultrasonic De-greasing Plant, PLC based Chain on Edge Conveyor, Anodizing Plant, Vacuum Emulsifying Blender, Mixers, Sachet and bottle filling Machines.

Machine shop (Precision Engineering) hands on experience with Lathe, CNC Milling, Shaper, Radial drill machine, EDM, Surface grinding and Wire-cut.

项目

工作经历

Executive (Head of Department)

Planning, organizing, leading, staffing and controlling of departments.

Project Management for New Product Development and development of existing products.

Production Management for sheet metal and plastic components, maintenance and trouble shooting of production machines, tools and allied equipments.

Quality Function Deployment, FMEA and building a House of Quality for existing and NPD.

Implementing Total Productive Maintenance culture.

Implementing Total Quality Management Tools.

Ensuring EHS implementation.

Ensuring KAIZEN 5S and its implementation.

Suppliers Management, selection of suppliers, pre and post evaluation, and building alliances with suppliers.

Stamping, deep drawing, injection and blow molding, pretreatment, anodizing, lacquering and quality control, trouble shooting and maintenance of machines and plant.

Designing of Production tools and their manufacturing using CAD software.

Machine Shop floor Management for manufacturing of production tools with precision engineering methods.

Supervising Construction works of factory.

Master Planning Schedule.

Mechanical Engineer

Manufacturing of different parts required by our customers such as, Extruder screws,

Extruder die set with nozzle, torpedo and other parts.

Designing and manufacturing of sheet metal dies and plastic injection moulds,

Rectification of Injection moulds and sheet metal dies for automotive components manufacturers.

Machine shop (Precision Engineering) hands on experience with Lathe, Milling, Shaper and Wire-cut and EDM Machine.