概要

PROFESSIONAL SUMMARY:

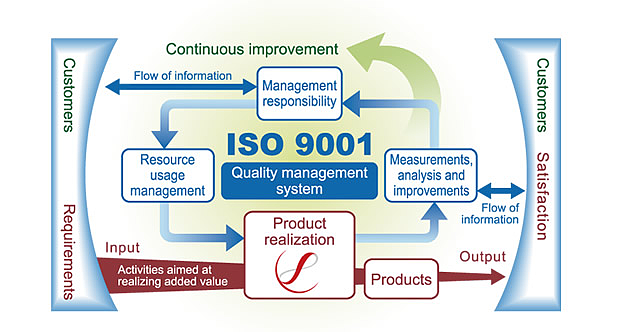

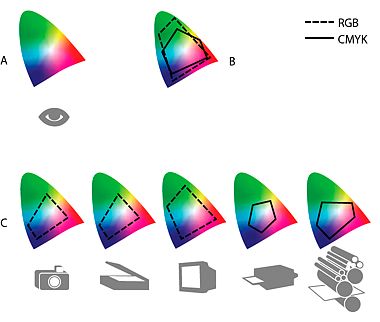

I am a associate engineer with effective management and supervision skills. I have the ability to control time and quality of production. Ability to analyze information and make timely decisions. Experienced in Quality Control / Quality Assurance, Development, Planning and Production. My expertise includes implementation in Quality Management System QMS (ISO 9001-2015) and Color Management System PSO (ISO 12647). Skilled in Sports Enthusiast, Quality Analysis, Management, Leadership, and Supervision, Strong printing professional with a DAE of ( Printing & graphic art -PGA ),

My key responsibility on here is to run the process as per schedule programmed. Manage Daily work flow of production staff. Make sure that production’s productivity and quality of printing, die, and pasting has to remains its optimum level. Processing the job card according to the product specification. To give color approval in printing sheet according to the client sample, shade card or pantone reference, position and other approval on the die cutting section, carton size and unit quantity packing approval in the pasting section.

SUMMARY OF SKILLS:

● Exceptional knowledge of , offset, screening as well as traditional printing.

● In-depth knowledge of the methods, techniques, guidelines and styles of print production.

● Deep knowledge of production management.

● Perform audits to ensure quality and quantity specifications and documentations.

● Strong knowledge of offset press-work procedures and materials.

● Proficient in MS Office and ERP Software.

● Skilled in reading, interpreting, and Hand held measurement equipments.

● Experience in production scheduling and knowledgeable of quality control standards.

● Keen observations on the procedures and the production making sure the quality work as high priority,

● Reporting the issue and responding corrective action to solve the problem quickly,

● Hands on knowledge and command on computer and software’s to carry out daily routine tasks,

项目

工作经历

Sr. Executive

Roles & Responsibilities:

· Carrying out all production processes as per SKU wise (Elly Card, Taffeta Labels, Paper Instruction,Warning Sticker & Brcode)

· Ensure timely completion of all production orders.

· Controlling production and quality standards.

· Barcode and printing department solving problems.

· Checking the barcode according to the barcode verifier ( A.B.C.D Categery Check)

· Find out barcode defect and resoled the issues ( just like Misprinting , Low Adhsive, Broken Bars, Low Ink, White Noise, Crooked,

White Blobs, Partially Covered, Damaged, Smudged )

· Monitor and manage inventory (Barcode Roll, Shipping Mark, Ribbon, Direct Thermal Barcode Roll).

· Limiting wastage by shortening downtime of machinery & preparationduration.

· Ensuring the day-to-day issues, i.e., machine breakdowns, are reported promptly to the concerned service department.

· Monitor repair andmaintenance.

· Controlling of Pre-Press, Press &Post-Press production on a routinebasis.

· Monitor and manage inventory (ink, chemical, paper & board, etc.)

· Arranging raw materials by month and order wise Preparing estimates and quotations.

· Prepare monthly raw materials consumption report.

· Prepare monthly production reports.

· Prepare monthly dispatch report.

· Manage dispatch planning as per scheduled programmed ETA.

· Managing Production, Planning, & Dispatch Of Offset Printing and Barcode Printing Division

· Responsible for production output, product quality, and timely dispatch.

· Investigate all the issues related to the process and find the root cause to avoid in the future.

· Schedule maintenance on all machines.

· Conduct customer approvals online on machines by coordinating with the marketing team.

· Monitor wastages (time and material) to make the process efficient.

· Make changes in the production plan to achieve production targets.

Assistant Production & Planning Manager

Key Responsibilities

• Retaining effective connection with the production, planning, marketing, commercial and graphic departments to ensure efficient utilization of the facility and other resources for optimum output.

• Increasing productivity by appropriate manpower planning & deployment.

• Limiting wastage by shortening downtime of machinery & preparation duration.

• Making sure the economics scale is in order by planning & scheduling an effective job.

• Ensuring the day-to-day issues i.e., machine breakdowns are being reported promptly to the concerned service department.

• Reporting to the Director Technical regularly for effective coordination and functioning of the overall department.

• Controlling production and quality standards.

• Make Docket (job Card) as per Order.

• Job planning according to the capacity and size of the machine.

• Manage planning and job run the process as per schedule programmed.

• Monitor repair and maintenance.

• Manage Daily workflow of production staff.

• Controlling of Pre-Press, Press & Post-Press production on a routine basis.

• To give color approval in Printing Section according to the shade card or Pantone reference.

• To give position and other approval on the Die Cutting Section.

• To Give Book Size, Spain, form sequence, and folio number approval in Binding Section.

• To give carton size and unit quantity packing approval in the Pasting Section.

• Verify print sheet size and grain and make cutting requisition paper and board.

• Ensuring that production productivity and quality of printing, die-cutting, and pasting have to remain at their optimum level.

Assistant Manager Pre-Press & Development

Key Responsibilities

• Developed new products by text, color, size, design, structure as per client need.

• Checking the accuracy and viability of the product specification.

• prepress inspection to ensure design proofing meet the client's standards before the production release.

• Make Shade Card as per client Need.

• Trail proofing & color Approval

• Incoming Material analysis and consumption reporting.

• Analyzing and interpreting test data and reliability of materials.

• Multi-tasked to keep all assigned projects running effectively and efficiently.

• Checked job Card information at each press to verify that the correct job delivered.

• GMG Project Work.

● Promptly removed completed loads from the press.

● Ensuring printing quality is meeting expectations of clients.

● Analyzing and interpreting test data and reliability of materials.

● Monitors jobs to ensure quality and compliance with job standards.

● During production runs to maintain specific registration and color densities

Production Supervisor

Responsibilities

● Keep record of daily production.

● Maintain all particular register department wise.

● Measure and report the effectiveness of warehousing activities and employees performance .

● Organize and maintain inventory and storage area.

● Determine staffing levels and assign workload.

● Maintain items record, document necessary information and utilize reports to project warehouse status.

● Identify areas of improvement and establish innovative or adjust existing work procedures and practices.

● Conferred and coordinate activities with other departments.

Composer & Salesman

Responsibilities

● Documents Composing like CVs, Letter Heads, Letters, Quotations etc.

● Computer Assembling

● Computer Hardware

● Fault Recognising

● Look after sales of Computers, LCDs, Computer Parts and Computer Accessories

● Windows Installation/Software Installation